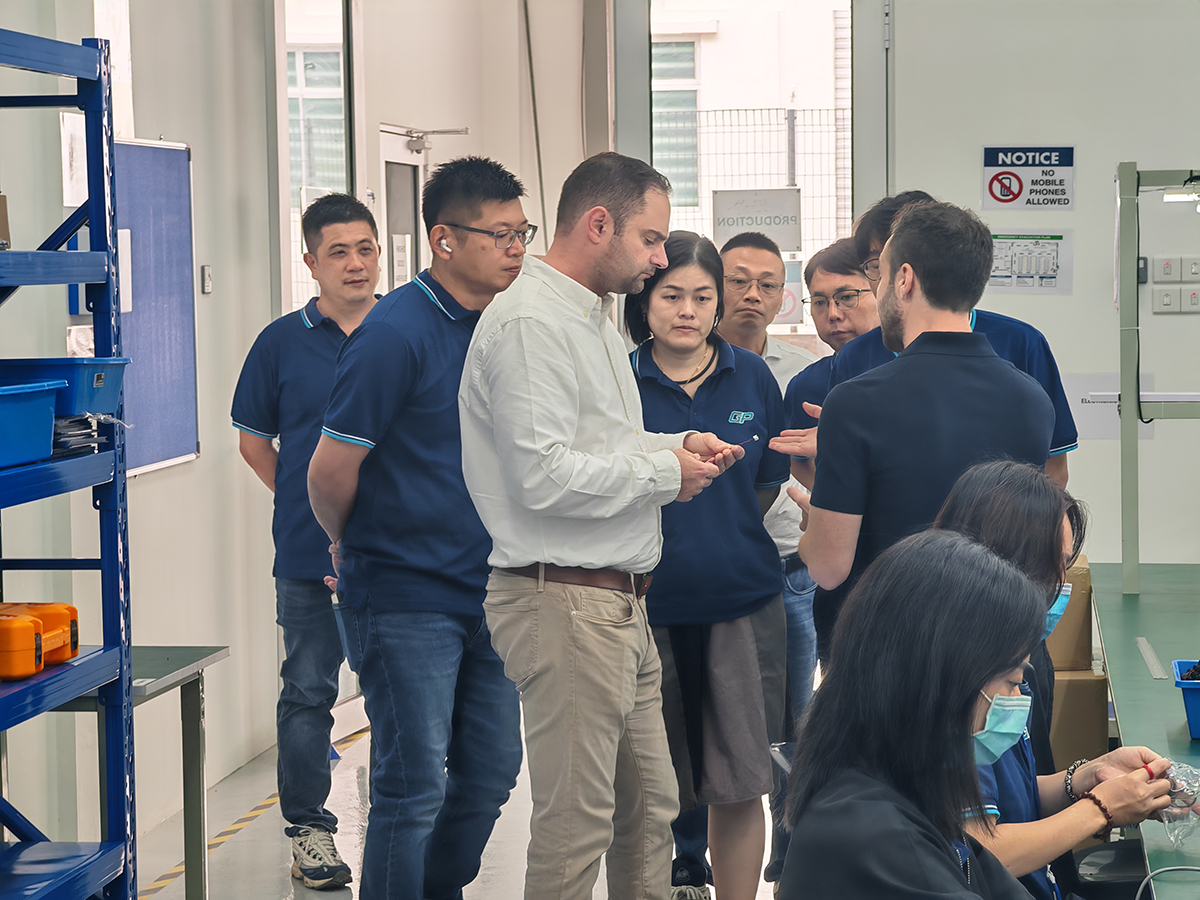

On December 17, 2025, the GPTEK factory in Malaysia welcomed an important international client for a factory inspection. This inspection not only tested our production quality but also conducted a comprehensive assessment of the factory's fulfillment of social responsibilities. The client conducted on-site visits, document checks, and employee interviews to conduct a detailed examination of the factory's operation management, production processes, and employee rights protection.

Lean production, with quality control throughout the entire process

Entering the production workshop, the automated wiring processing equipment is operating in an orderly manner. Workers are concentrating on conducting wiring, crimping and inspection operations. The review team thoroughly examined the entire process from raw material entry to finished product shipment, and expressed satisfaction with our IQC incoming material inspection, IPQC process control and FQC final inspection records. The factory strictly implements the ISO9001/IATF16949 quality management system. Quality tracking points are set up at each stage to ensure the reliability and consistency of the products.

Focusing on employees, social responsibility practices receive praise

During the factory inspection process, the auditing team focused on the factory's measures for safeguarding employees' rights and interests. We presented the auditing party with a comprehensive salary system, compliant working hour management system, and a safe and healthy working environment. The factory workshop was equipped with ventilation and cooling equipment, protective gear, and regular safety training to ensure that employees work in a comfortable and safe environment. The auditing team particularly commended the factory's transparent approach in the communication mechanism for employees, including regular meetings and anonymous feedback channels, truly embodying the management philosophy of "focusing on employees".

Continuous improvement to provide reliable guarantees for customers

To prepare for this factory inspection, we conducted internal investigations and optimizations three months in advance, including updating the document record system, strengthening 6S on-site management, and improving emergency response plans. During the inspection process, employees from all departments cooperated actively, and smooth communication and professional responses demonstrated the team's collaboration ability. Finally, the factory passed the audit with zero serious non-conformities. The customer representative said, "GPTEK's solid work in quality management and social responsibility is impressive. We look forward to long-term cooperation."

The success of this factory inspection has further strengthened our competitive edge in the wire harness manufacturing sector. In the future, we will continue to invest in the upgrading of intelligent production lines and deepen the concept of green manufacturing, providing global customers with safer and more efficient wire harness solutions.